1, Load Feature:

(1) Both of them belong to fluid control.

(2) If without VFD, fluid is controlled by valve or baffles

(3) For less fluid required system, there will be more energy saving

(4) In theory, if the running frequency is H1, then Energy Saving = 1-(H1/50)3

2, Requests For VFD:

(1) Soft start the motor, reduce the surge current.

(2) VFD should work continuously without fault.

(3) Speed tracking and start (flying start) function should be reliable

(4) In some systems, PID function is required.

3, Real example:

In a hotel, there is an central air-conditioner, the cooling fan is one PCS of 15kW motor,in one year,it runs 4000h, 2000h with the air flow of 85%, 2000h with the air flow of 60%

*Power Consumption Without Frequency Inverter

(15KW X 91%X2000H)+(15KWX76%X2000H) = 50,100KWH

Power of 85% Flow ,Power of 60% Flow

Note: 91% and 76% are empirical value

*Power Consumption With Frequency Inverter

(15KW X85% X2000H)+(15KW X60%X2000H)= 24,900KWH

Power of 85% Flow ,Power of 60% Flow

Engergy Saving in one Year: 50,100KWH-24,900KWH=25,200KWH/Year

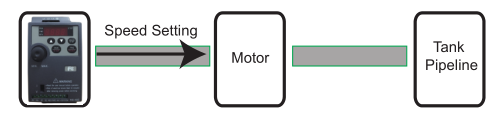

4, System Diagram:

5, Wire Diagram:

6, Parameter Setting Step:

Step | Function Code | Factory Default | Set Value | Description |

1 | P102 | 0 | 1 | The Operation Setting is Selected as I/O Terminal |

2 | P101 | 3 | 1 | Frequency setting selection analog voltage mode |

3 | P104 | 1 | 0 | Reverse Prohabit |

4 | P107 | Change | Set as need | Acceleration time |

5 | P108 | Change | Set as need | Deceleration time |

6 | P201 | 0 | Fan Suggest 1 | Stop Way |

7 | P317 | 9 | 17 | Emergency Stop |